CNC Equipment

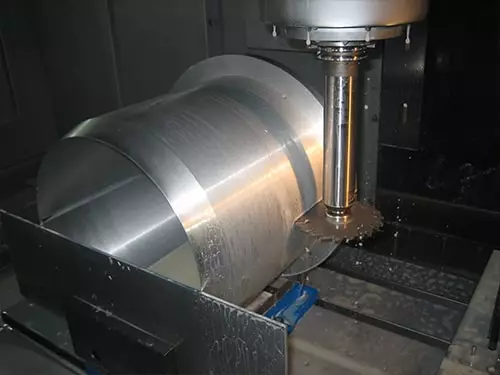

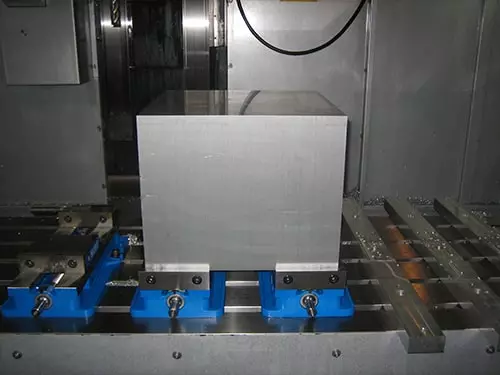

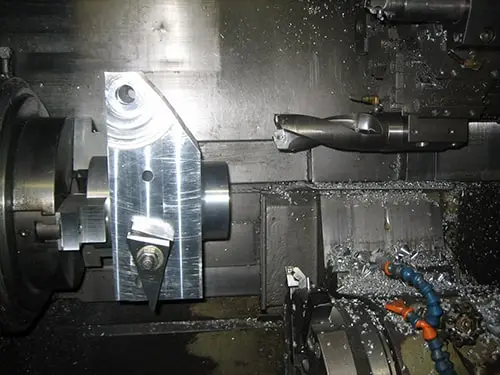

GPM's Skilled programmers set up our CNC Lathes and Mills to efficiently run larger quantities as well as to produce one piece detailed parts.

CNC Mills

- Sharp SV6030 3 axis VMC 60" X 30" X 27"

- M-12 acroloc 4 axis VMC 31.5" X 14" X 20"

- Kitamura My Center One 4 axis VMC 18" X 12" X 16"

CNC Lathes

- 35-C Kingston 4 axis twin turret CNC lathe 18" dia. X 13"

- 35-C Kingston 4 axis twin turret CNC lathe 20" dia. X 13"

- Femco HL25 CNC lathe 17" dia. X 23"

- Ikegai AX20X CNC lathe 16” x 23”

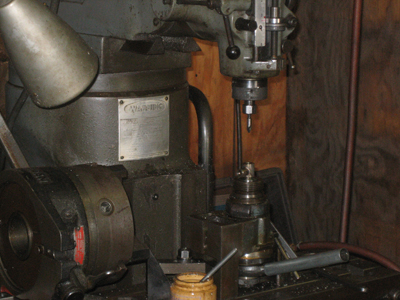

Garland’s Manual Support Equipment

GPM uses our manual support equipment to produce tooling used to manufacture parts in house reducing turn around time. Support equipment is also used to add finishing touches such as tighter tolerances or fine finishes to precision machined parts.

Our second operation capabilities include honing, deburring, gear hobbing, thread rolling, knurling, and more.

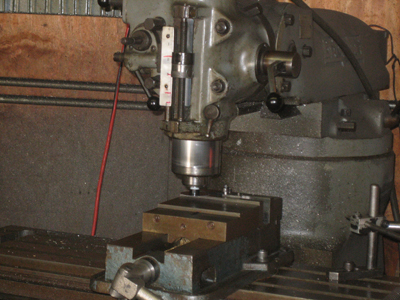

Milling

- J-2 Bridgeport Vertical Mills – 12" X 24" (quantity two)

- 850 Moriseiki engine lathe – 12" dia. X 24"

- 850G Moriseiki engine lathe – 24" dia. X 24"

- 1805 Sunnen hone

- K.O. Lee surface grinder

- Cutter Master grinder with radius attachment

Sawing

- W-10-2U W.F. Wells automatic horizontal band saw

11"x 18" - 4V-18 Grob vertical band saw - 18"

- Brilliant 12" mitering chop saw

- 12" mitering radiac saw

- Baldor grinders

- 12 speed heavy duty drill press

- 16 speed heavy duty drill press

- Rockwell International drilling & tapping machine