Precision CNC Machining Services: Serving Southern California Since 1974

When you review even just some of the machined parts produced by Garland’s Precision, Inc. it’s clear to see why Southern California Aerospace, Medical, and Commercial companies turn to the this family owned and operated precision machine shop for high quality, cost effective manufacturing solutions.

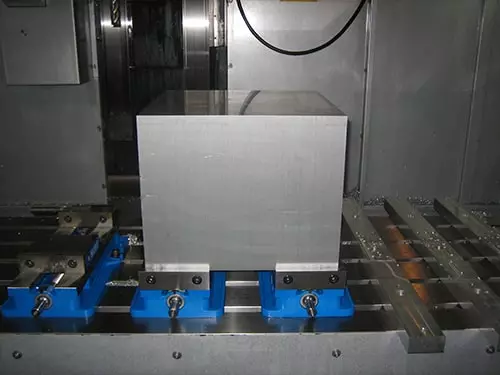

The Garland’s team specializes in providing precision CNC machined parts and mechanical assembly services, with sizes ranging from smaller than a pencil eraser to components or assemblies weighing as much as 1000 pounds.

AND all this is done holding tolerances as tight as plus or minus .0002.

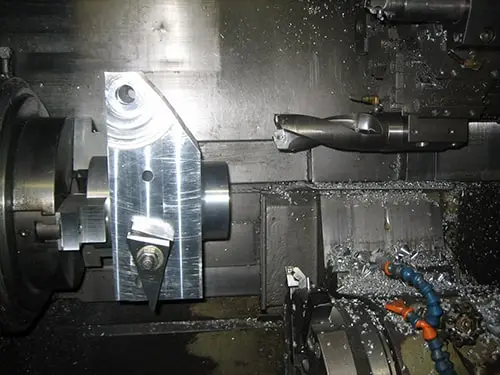

Whether it is CNC Milling Services, CNC Turning Services, Metal Fabrication Services, or Mechanical Assembly, Garland’s can work from various forms of technical information including 3D cad files, 2D blueprints–or even a sample of the component or assembly to be manufactured. We are proficient in manufacturing highly complex components and assemblies.

With Garlands’ no job is typical–the quantities of components manufactured range from a single prototype to full scale production of thousands of pieces.

CNC Precision Machining Materials and Metal Fabrication Services

Garland’s Precision Inc. is familiar with many types of material from aluminum and polymers (plastic) to exotic high temp alloys in many different forms including bar stock, castings, and forgings.

This landing gear assembly/disassembly tool showcases some of the smaller components we manufacture, as well as illustrates the various different materials we work with such as tool steel, stainless steel, delrin, and aluminum.

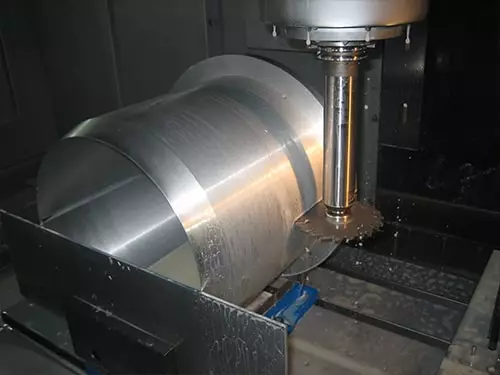

Additional specialties include hard milling and hard turning of heat treated alloy, stainless, or tool steels up to 62 Rc hardness, often times eliminating the need for secondary grinding or EDM operations.

California CNC Machining Companies: Garland’s Competitive Advantages

As shown with this image Garland’s Precision Inc. is capable of producing highly complex threads such as multi start acme or buttress threads.

We achieve this by employing many different techniques such as thread milling, single point threading, or roll forming of threads for increased strength.

Other areas where Garland’s Precision Inc. excels include milling and turning of deep cavities or thin walled components. In addition, we also perform many value added secondary operations in house such as part marking or honing to a mirror like finish.

A good example shown are these various different support lockout components used for aircraft assembly. All were manufactured, assembled, and boxed for storage to our customer’s specification.

Each component has unique identification, orientation, and serial numbers all engraved and paint filled by GPM.

Since 1974 Garland’s Precision, Inc. has been the shop that California companies have come to rely on for expert CNC machining services.